Add to Cart

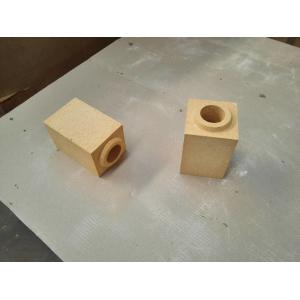

High Temperature Fireproof Stopper Refractory Sleeve brick for casting steel/iron steel industry

We can offer a complete range of High Temperature Fireproof Stopper Refractory Sleeve brick for casting steel/iron steel industry. In order to meet the specific requirements of each steel plant, we has set up a vast assortment of moulds and is therefore in a position to produce custom-made products or special shapes according to different production requirements.

Beside fireclay,the other raw materials such as shale,gangue,fly ash could also be used for square runner bricks production.Although they are similar in chemicals with fireclay, they need to be combined with fireclay for brick production due to lower plasticity. In addition, the gangue and fly ash in the brick are flammable industrial waste containing cabon residue. They will burn inside the brick when calcination which helps save coal consumption volume. As a result,these type of bricks are also called Inner flammable bricks and semi-inner flammable bricks.

Technical data

| Description | 40% | 50% | 60% | 70% | 80% | |

| Bulk Density | g/cm3 | 2.15 | 2.2 | 2.3 | 2.4 | 2.5 |

| Apparent Porosity | % | 24 | 24 | 24 | 23 | 23 |

| Cold Crushing Strength | MPa | 30 | 40 | 45 | 50 | 55 |

| Refractoriness | ℃ | 1710 | 1730 | 1750 | 1800 | 1830 |

| Softening temperature under load | ℃ | 1350 | 1430 | 1450 | 1500 | 1550 |

| Chemical Composition | % | |||||

| -Al2O3 | 40 | 50 | 60 | 70 | 80 | |

| -Fe2O3 | 2.5 | 2 | 2 | 2 | 2 |